Next Generation LAUE System

A high-resolution Crystal Orientation System is the ideal tool to capture and analyze the Laue diffraction pattern from a wide range of crystalline materials. Dedicated software enables quick and accurate measurement of single-crystal orientation..

Key Features

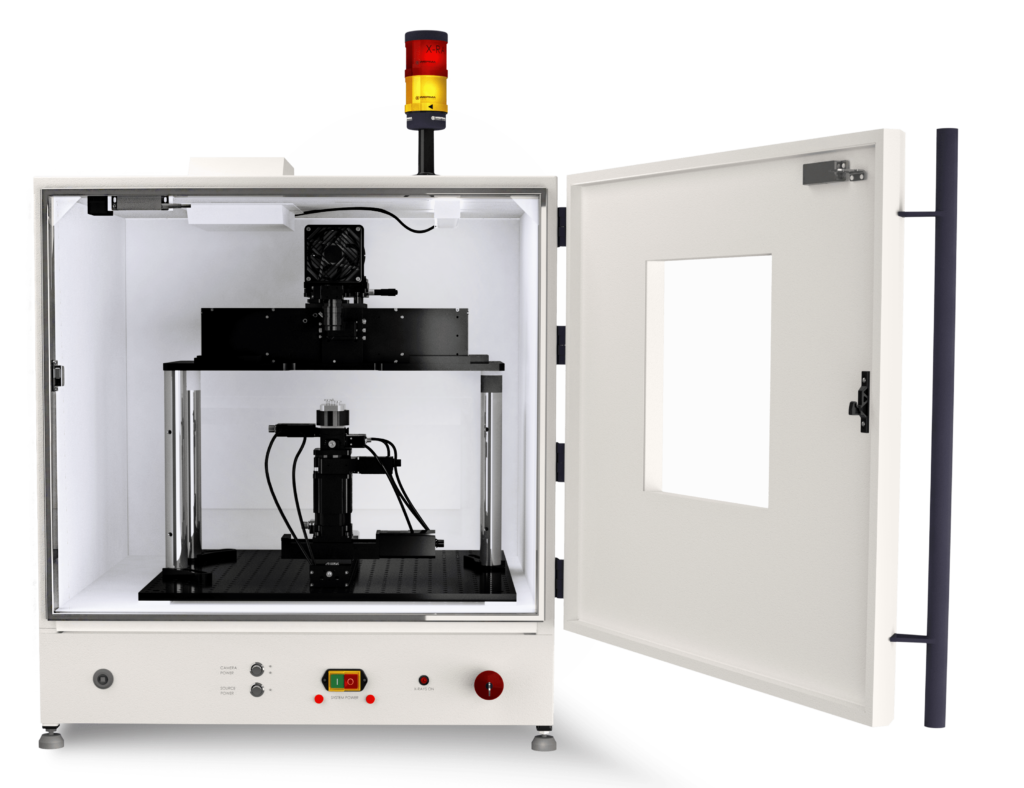

- Available in Vertical, Horizontal, and Grain Map configurations

- Plug-and-play compact cabinet system - no customized bench or additional services required

- Fully automated, motorized XYZ stages and Goniometer, with manual options available

- CCD back reflection, high-resolution, high-sensitivity X-ray detector

- Proprietary focusing optics giving a small collimated beam size

- Fast and precise alignment of small crystals with on-board high-resolution viewing camera

- Distance measurement tool for precise and reproducible sample positioning

- Dedicated Laue Software for full control, data acquisition, processing and analysis

- High-throughput sample screening options

Vertical Configuration

The most flexible configuration, the Vertical LAUE system uses a vertical beam path for high throughput scanning of multiple crystals in isolation or multiple areas of interest. Using gravity, samples do not need to be adhered to the platform, allowing for easier mounting, and orienting of crystals. With a <200µm beam size both sub-millimetric range samples and larger components like turbine alloys are accommodated.

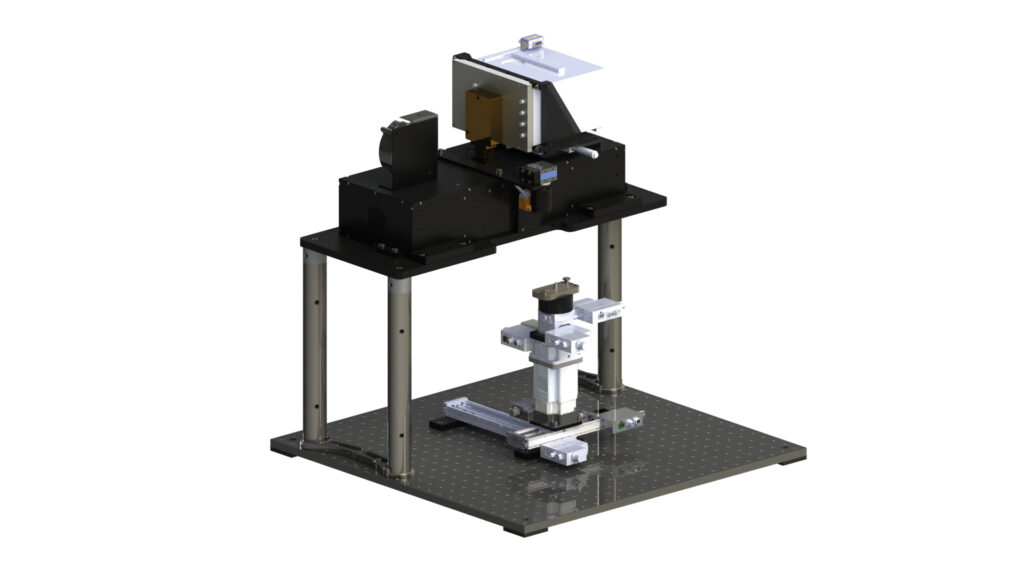

Horizontal Configuration

The LAUE System is also available with a traditional horizontal geometry. A horizontal LAUE System is well suited to orient the crystal for cutting or to quickly scan the crystal to identify reflections.

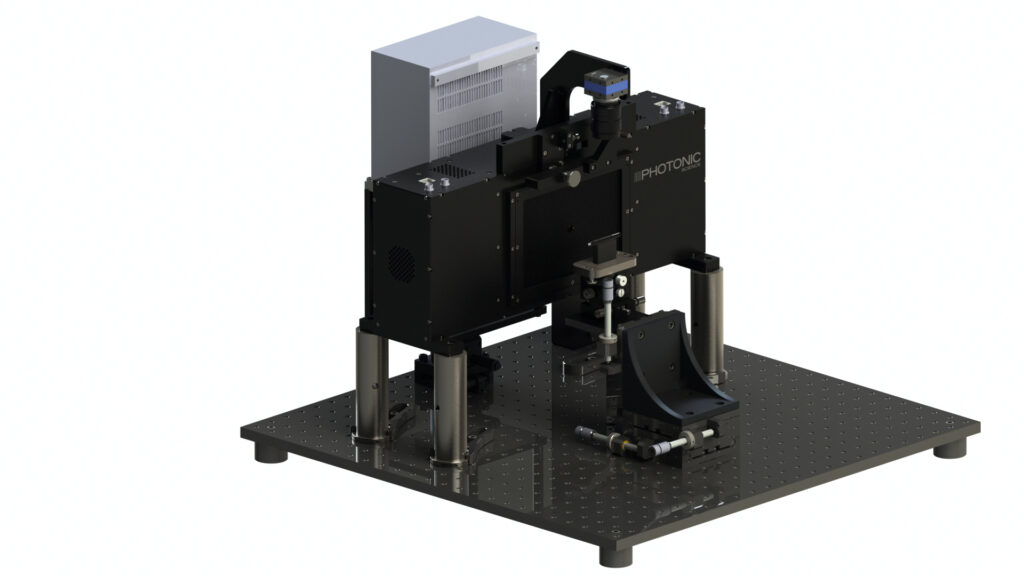

Grain Map Configuration

A vertical system featuring a special camera, lens, illumination, and mapping software to measure the orientation of each grain. Grain Map includes a fully motorized XYZ Stage and Goniometer as standard, and is ideal for grain mapping silicon wafers.

Main Specifications

| Large Active Area | 155 mm x 105 mm |

| High Resolution | 2,500 x 1,650 pixels |

| Input Pixel Size | 60 µm x 60 µm |

| Spot Size | Down to 200 µm |

| Energy Range | 5 to 50 keV |

| Source | 50W |

System Option

| Manual Option | Manual XYZ Stage and Goniometer |

| Motorized Option | Motorized XYZ Stage and Goniometer |

| No Goniometer Option | Motorized XYZ Stage - NO Goniometer |

| Fine Focus Option | Vertical Configuration only |

| Customized Solution | Fully customizable systems available |

Applications

- Crystal Growth

- Real Time Crystal Orientation

- Crystal Characterization

- Crystal Cutting

- Photovoltaic Inspection

- Two-Dimensional orientation mapping of polycrystalling silicon wafers

- Semiconductor Crystals

- Wafer Inspection

LAUE Image Alignment Software

- Automatically detects diffraction spots and calculates spot position against reference crystal

- Automatically calculates mis orientation against goniometer and crystallographic axis (no manual fit or distorted patterns)

- Intuitive workflow for multiuser operation and non-expert crystallography users

- Save angular measurements in CSV format for Quality Assurance traceability

- Built-in Macro interface for automating repetitive routines

- Compatible with CFL data files

- Remote access control for ongoing service support, minimal downtime